CNC (Computer Numerical Control) programming is a fundamental aspect of modern manufacturing. It involves the use of computers to control machine tools such as lathes, mills, and routers to create precise and intricate parts. By converting design models into machine-readable code, CNC Programming enables automated production processes that ensure high accuracy, repeatability, and efficiency. This article explores the concept of CNC programming, its significance in various industries, the process involved, and its future implications.

What is CNC Programming?

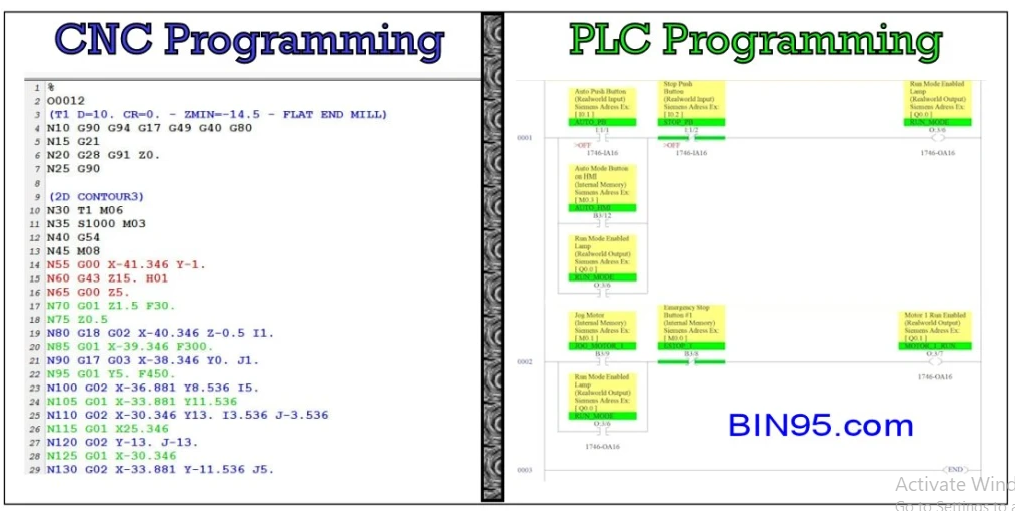

CNC programming is the process of creating instructions for CNC machines to follow in order to manufacture a specific part or product. These instructions are written in programming languages like G-code and M-code, which are interpreted by the CNC machine to execute tasks such as cutting, drilling, shaping, and finishing materials. Unlike traditional manual machining, where operators physically control the machine, CNC programming allows for automated, highly accurate, and repeatable operations.

The key advantage of CNC programming is its ability to produce complex and precise components with minimal human intervention, significantly reducing the chances of errors and increasing production efficiency. It also enables manufacturers to maintain high-quality standards and quickly adapt to different production requirements.

The Role of CNC Programming in Modern Manufacturing

CNC programming has become the backbone of precision manufacturing in various industries, including aerospace, automotive, medical device production, electronics, and more. Here are some of the key ways CNC programming plays a critical role in modern manufacturing:

1. Precision and Accuracy

One of the primary benefits of CNC programming is the level of precision it offers. CNC machines are capable of producing parts with tolerances in the micrometer range, which is essential in industries where even the smallest deviation can result in product failure. This level of accuracy is difficult to achieve with manual machining processes, making CNC programming indispensable for high-precision manufacturing.

2. Complexity and Customization

CNC machines are capable of creating highly complex and intricate parts that would be impossible or time-consuming to produce manually. With CNC programming, manufacturers can design and produce customized components tailored to specific requirements. This versatility is especially useful in industries like aerospace and medical device manufacturing, where bespoke parts are often needed.

3. Repeatability and Consistency

Another significant advantage of CNC programming is its ability to produce identical parts in high volumes without any variation in quality. Once a CNC program is created and tested, the machine can repeat the same operation with consistent results, ensuring that each part meets the required specifications. This repeatability is essential for industries that rely on large-scale production, such as automotive manufacturing.

4. Efficiency and Time-Saving

CNC programming enables faster production processes by automating tasks that would otherwise require manual effort. Additionally, CNC machines can work continuously, reducing downtime and speeding up the manufacturing cycle. This is especially beneficial for mass production runs, as it allows manufacturers to meet tight deadlines and produce large quantities of parts in a shorter amount of time.

The CNC Programming Process

CNC programming involves several steps to ensure that the machine executes the desired task correctly. Here is an overview of the typical CNC programming process:

1. Design and CAD Model

The first step in CNC programming is the design phase, where engineers or designers create a 3D model of the part to be manufactured. This model is typically designed using Computer-Aided Design (CAD) software. The CAD model serves as the blueprint for the CNC program, helping programmers understand the part’s dimensions, features, and material specifications.

2. Converting the CAD Model to a CNC Program

Once the design is finalized, it needs to be converted into machine-readable code. This step is where CNC programming comes into play. Using Computer-Aided Manufacturing (CAM) software, the 3D CAD model is converted into a CNC program, typically written in G-code or M-code. G-code is a language that instructs the CNC machine on how to move the cutting tool, while M-code controls auxiliary functions such as coolant and spindle speed.

3. Toolpath Creation and Simulation

After the CNC program is generated, the next step is to define the toolpath—the specific path the cutting tool will follow to shape the material. The toolpath is determined based on factors like material type, cutting speed, and machine capabilities. CAM software allows programmers to simulate the toolpath to check for any potential errors or collisions before running the program on the actual machine. This helps prevent damage to the machine and ensures that the part will be produced correctly.

4. Verification and Testing

Before the CNC machine starts the actual production, the program is verified to ensure that all commands and tool paths are correct. This is done through simulation or testing on the CNC machine. Any errors in the program, such as incorrect tool movements or cutting speeds, are corrected at this stage.

5. Production and Monitoring

Once the CNC program is verified and tested, it is loaded into the CNC machine, and the production process begins. During production, operators and engineers monitor the machine to ensure that the process is running smoothly. If any issues arise, adjustments can be made to the program or machine settings to resolve the problem.

6. Post-Processing

After the part is manufactured, it may require additional post-processing steps, such as cleaning, deburring, or finishing. These steps can be automated or done manually, depending on the complexity of the part and the requirements of the final product.

Key CNC Programming Languages

CNC programming typically uses two main languages to instruct the machine: G-code and M-code.

1. G-Code

G-code, or Geometric Code, is the most widely used CNC programming language. It provides detailed instructions to the CNC machine on how to move the cutting tool along specific paths, how deep to cut, and the type of movement required. For example, G-code can specify commands for linear and circular movements, tool changes, or feed rates. Some common G-code commands include:

- G0: Rapid positioning (moving the tool quickly to a specific location)

- G1: Linear interpolation (moving the tool in a straight line)

- G2: Circular interpolation (moving the tool in a clockwise circular path)

- G3: Circular interpolation (moving the tool in a counterclockwise circular path)

2. M-Code

M-code, or Miscellaneous Code, is used to control auxiliary functions that are not related to the movement of the tool. M-codes control actions such as starting and stopping the spindle, turning coolant on and off, or changing tool offsets. Some common M-codes include:

- M3: Start the spindle in a clockwise direction

- M5: Stop the spindle

- M8: Turn on coolant

- M30: End the program and reset the machine

Benefits of CNC Programming

CNC programming provides several advantages to manufacturers and industries alike. Some of the key benefits include:

1. Improved Precision and Accuracy

With CNC programming, manufacturers can achieve a level of precision and accuracy that is not possible with manual machining. CNC machines can produce parts with extremely tight tolerances, which is crucial in industries like aerospace and medical device manufacturing.

2. Cost-Effectiveness

Although the initial investment in CNC machines and programming software can be high, the long-term cost savings are significant. CNC programming reduces the need for skilled labor, minimizes human error, and improves production efficiency, resulting in lower operational costs over time.

3. Increased Productivity

CNC machines can operate continuously, producing parts with minimal human intervention. This leads to higher productivity and faster turnaround times, especially in high-volume production environments.

4. Flexibility and Customization

CNC programming allows for easy customization of parts. With just a few adjustments to the CNC program, manufacturers can produce parts with varying shapes, sizes, and features without having to retool the machine.

5. Enhanced Safety

CNC machines operate with minimal human intervention, reducing the risk of accidents and injuries that can occur in manual machining processes. Additionally, many CNC machines are equipped with safety features such as emergency stop buttons and protective enclosures.

Challenges and Future of CNC Programming

Despite its numerous benefits, CNC programming is not without its challenges. One of the main hurdles is the steep learning curve for new programmers. Mastering G-code and M-code can take time, and the complexity of the program increases as the part design becomes more intricate. However, advancements in CAM software and automation tools are making it easier for engineers and programmers to create CNC programs.

Looking to the future, CNC programming is expected to become even more advanced with the integration of artificial intelligence (AI) and machine learning. These technologies will allow CNC systems to automatically optimize programs and improve their performance based on real-time data, further enhancing efficiency and productivity.

Conclusion

CNC programming is a cornerstone of modern manufacturing, enabling industries to produce high-quality, precise, and customized parts efficiently. As technology continues to evolve, CNC programming will become even more sophisticated, with greater automation, improved software, and enhanced capabilities. With its numerous benefits, CNC programming will continue to play a pivotal role in shaping the future of manufacturing across a wide range of industries.